Nuclear Reactor Control Rods

Sometimes people ask me what the control rods in nuclear power plants are. Well, here's the answer:

Uses of control rods

Nuclear reactor control rods have three primary types

- Safety rods – These rods have a high overall "rod worth." These are used for emergency shutdowns. They must reduce reactor power below a certain amount within a specific time frame. The rod worth is the stopping power of the control rod in slowing a fission reaction.

- Flux peaking rods – These control rods control local neutron flux levels. They control fuel usage and maintain it within a specific band for localized fuel burnout. The flux profile can be shaped to match the engineered ideal profile by raising and lowering these rods with a relatively low rod worth. Think of it as braking and accelerating your car in the most efficient way to save gas.

- Power control rods – This type of rod is used for the overall control of reactor power during transient power changes. They may have a faster rod speed than other rods in use. These rods are used to control coolant temperatures when operating at power. Borated water may be used in some circumstances instead of control rods to control reactor power levels. This is called a "chemical shim, " providing a more even neutron flux change. Also, variations in recirculation pump speeds in BWR designs will change the coolant-to-steam ratio inside a fuel channel and, based on the void coefficient, change reactor power levels. These are alternative methods of varying power levels without using control rods.

Principles of Operation

All control rods must operate on two primary principles.

- They must operate fast enough to overcome a peak end-of-life xenon transient following a reactor shutdown to prevent xenon-precluded startup. This allows the reactor to reach the design end of core life without being limited by fission product poisons. What does that mean? Well, sometimes nuclear poisons (not people poisons, these prevent fission from happening by absorbing neutrons) build up in the core following certain power transients. To overcome Xenon poisoning, your control rods must be fast enough to change your neutron flux rate to keep up with the adverse effects of the poisons.

- They must operate slow enough to allow operator action to prevent a power excursion during a rod withdrawal casualty. If rod speed is too great, a rod withdrawal casualty will cause an uncontrollably high startup rate that will cause a peak reactor power level above thermal limits.

This is the Rod Position Indication used at the Chornobyl power plant. Each dial shows the position of the control rod. Spread throughout the panel are local power level indicators. Due to the size of the Chornobyl power plants, one part of the core could operate critically while another portion remained subcritical.

Design of control rod drive mechanisms

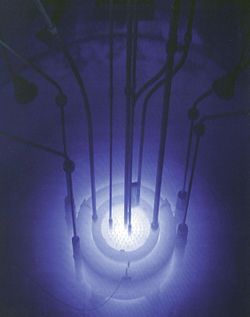

Control rods may be inserted either via the top of the reactor vessel through the flange or the bottom of the vessel, such as in boiling water reactors. CRDMs may either function off of an electric motor or hydraulically. The electric motor type system will rotate, causing insertion or withdrawal of the control rod via a lead screw attached to roller nuts. The hydraulic system will cause the differential pressure across a drive piston to force the rod inward or outward depending on the position of directional control valves. This is an example of hydraulically operated control rod drive mechanisms.

Member discussion