Jominy End-Quench Testing

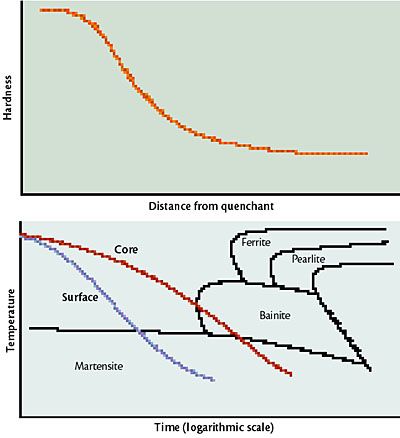

The Jominy end-quench test procedure is a test that measures a specific material's ability to be hardened. What this means is that, in the case of iron, the ability of the material to transform from austenite to an amount of martensite. What this really means is how well the material’s crystalline structure converts from one arrangement to another. Manufacturers care about this because it lets them know how well a heat treatment will work on a given alloy.

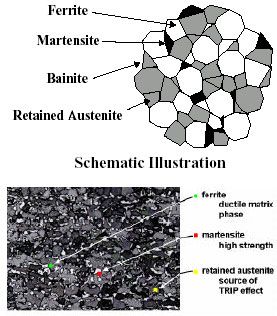

Hardening is the process by which a metal is treated to adjust the hardness to a desired level. Hardness is defined as the ability of a material to resist plastic deformation due to a higher uniaxial yield stress at the location of the tested strain. The five hardening processes are the Hall-Petch method, work hardening, solid solution strengthening, precipitation hardening, and martensitic transformation. Other heat treatments may take the form of annealing, stress relieving, normalizing, aging, tempering, hardening, or quenching. Martensitic transformation is the type that utilizes quenching. What all of these processes do is change the physical structure and sometimes the chemical composition of the steel. Below is a schematic showing some of the structures found in steel.

The Jominy end-quench test is actually performed by taking a test sample rod, heating the sample to a high temperature (800C-925C), then placing in the test container and spraying it with water as seen above. After that, the material is ground down (taking care not to heat the material in doing so) and measuring hardness.

This test was created by an automotive engineer named Walter Jominy in order to ease the problems associated with calculating hardenability in steel. Previously, thousands of curves and tables were required in order to accurately plot the hardness of a material. With the invention of this test, engineers could easily do the test themselves. Other hardening tests include the Grossman test and the S-A-C test.

Member discussion