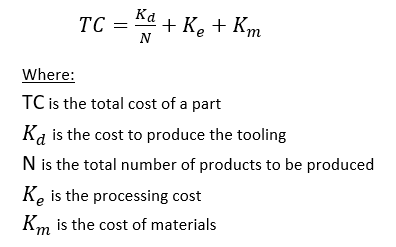

Injection Mold Total Cost Equation

The cost to produce tooling and dies is typically normalized across the expected production volume. This causes small production runs to have a larger overall impact on the total cost of a part. As the volume goes up, the cost of tooling becomes less relevant. Below is an equation to help compare break-even points for molded parts. Use this equation to figure out the best value for your product when comparing tooling solutions.

Processing costs are those required to operate the machinery necessary to produce the part. It also includes the cost of labor and overhead. The processing cost cannot be reliably estimated until after the parametrized design has been completed. Often the total machine tonnage in use is used to estimate processing costs. In the early stages of a product design, it is almost impossible to estimate processing costs reliably.

Material costs are the total cost of the materials required to produce the part. Something like ABS is relatively expensive, whereas polypropylene is extremely inexpensive. Polystyrene tends to be a mid-range cost material.

Mold closures are vital for consideration by the design engineer when it comes to designing an injection molding part. Incorrectly applying a feature may result in an undercut mold requiring special tooling. Similarly, parting must be considered as well. Assuming an incorrect parting direction will also result in special tooling being required for the mold to function normally. The design engineer must remember that undercuts are both a function of the part geometry and the mold parting direction.

Member discussion