Design for Manufacturing: Stamping Presses

This rule provides instructions on selecting presses in stamping operations based on the part type and speed.

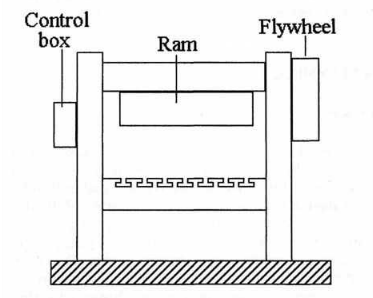

Stamping presses comprise a frame, a bed, a ram or slide, a drive for the slide/ram, and a power train, including a transmission. Power may be supplied either hydraulically or mechanically.

Presses may have one or more action types. An action is a stroke that produces a result on the part being worked. Each level of stroke will typically require an additional ram used. Most hydraulic presses are double-action presses that use one ram to position and seat the part while a second ram performs work on the part. Mechanical presses use a flywheel that runs continuously. A clutching mechanism pulls energy off the flywheel when a stroke is required.

Hydraulic presses may be selected when the maximum force of the stroke is required at the start of the stroke (such as in deep drawing applications). Hydraulic presses are much slower than mechanical presses, with an order of magnitude difference in speed being common. Hydraulic presses tend to be much less expensive when compared to mechanical presses.

While designing products that will utilize stamped components:

(a) If the part volume is low (less than 100,000), consider using a hydraulic press.

(b) If the part volume is higher, consider using a mechanical press, as tooling costs will be negligible.

(c) Use a hydraulic press if the part requires finely adjusted or constant stroke pressure.

By following this rule, product designers will produce lower-cost parts when stamping is used.

Member discussion