Design for Manufacturing: Shaft Keyways

Keyways are cut into shafts to connect them to another object. Typically, this transmits rotational energy by providing a transmission path from the shaft into the adjacent object through a keyed joint. Typically keyways are parallel to the shaft and are rectangular.

Keyway design is most economical when a single cutter can be used throughout each step of the manufacturing build. This can be accomplished by selecting the keyway size to allow for using a single cutter throughout the entire keyway cutting operation.

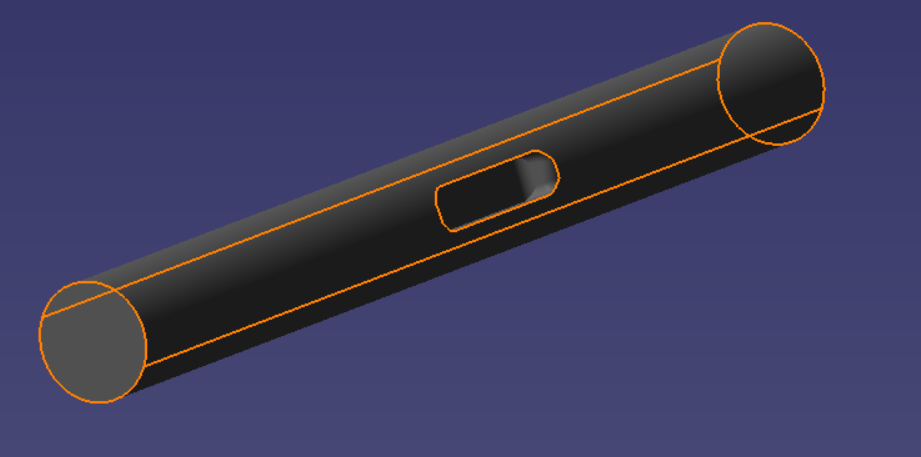

Additionally, rounded ends should be used in the keyway rather than square ends, allowing a single cutter to provide both the horizontal and vertical cuts necessary to create the shape. No cutter change-out is required. To ensure minimal costs, select a standard cutter size to prevent excessive tooling costs or additional cutter grinding requirements.

Key points:

If the part will contain a keyway cut...

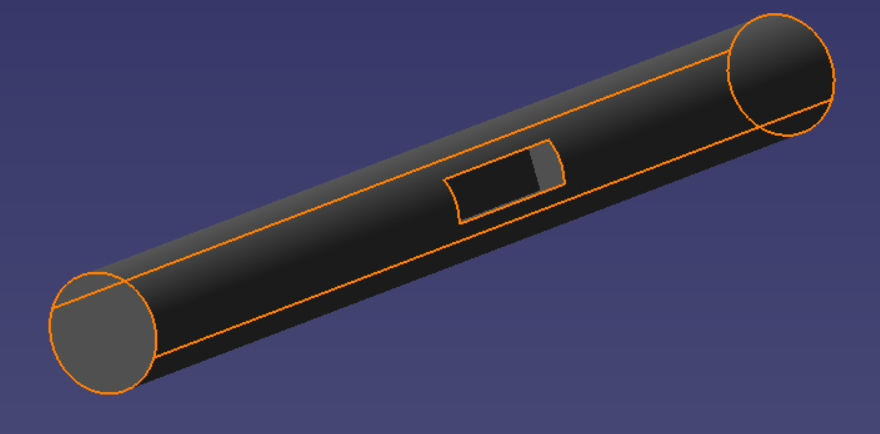

(a) Avoid designing square edges on the internal faces of the keyway cut.

(b) Avoid ending the keyway at a radius that does not easily permit the same cutter to be used throughout the entire keyway cut.

Using the ideas presented in this article, keyway cuts in milling have significantly reduced tooling costs and time requirements. This drives processing costs down.

Member discussion