Design for Manufacturing: Machined Corners

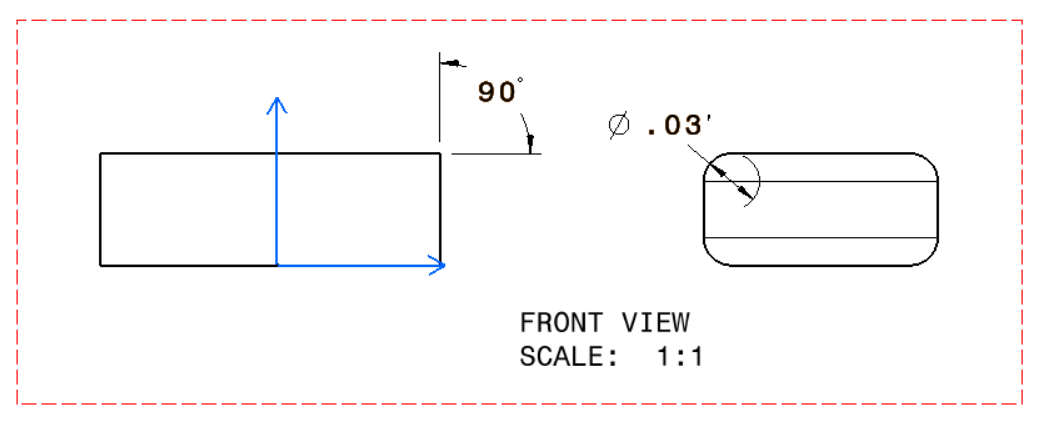

This article explains the difficulties associated with machining sharp corners and why to avoid them.

Machining is a subtractive manufacturing technique (as opposed to 3d printing, which is additive manufacturing!) that utilizes rapidly rotating cutters to remove undesired materials from a block of material. These blocks are usually metal; however, composite materials are also frequently machined.

Whenever designing a machined part, consideration should be given to the avoidance of sharp corners. Sharp corners require particularly sharp cutter blades. As sharp blades have less effective surface area on the blade surface making contact with the workpiece, the concentrated forces on the blade are higher. This means you're more likely to break your cutter, which can cause a delay in your production flow. You also have to pay for a new tool which can be expensive.

A brittle fracture of a material occurs when a susceptible material with a preexisting flaw is subject to tensile stress. Cutter blades are subject to both tensile and compressive stresses when used to machine a workpiece. When extremely sharp corners are necessary, an extremely sharp blade will also be necessary. As this blade will have a small surface area, overall forces felt are greater per unit area. This will result in a higher chance of fracturing.

If

You are designing machined parts

Then

(a) Avoid the use of sharp corners

(b) Preferentially design rounded corners when machined tolerances are necessary.

Use of this rule will prolong cutter life and decrease potential product damage due to fracturing cutters mid-machining. In the event of composite machining, this will likely prevent the destruction of the workpiece due to delamination.

Member discussion